☑ Renouvellement des certificats ISO 9001 et 14001

Cutting

Our

know-how

in cutting

Our recognized expertise and our machine park of traditional presses and multiple slides allow us to manage the cutting of your industrial parts.

Nos méthodes de production

From tooling to cutting

The tooling leaving our tooling workshop is taken care of by our technicians who ensure the production of your parts in our traditional press and multiple slide cutting workshops.

Since production is the object of all our attention, we carry out a rigorous control of the operation of the presses and the tools in order to preserve the quality and the conformity of the parts produced.

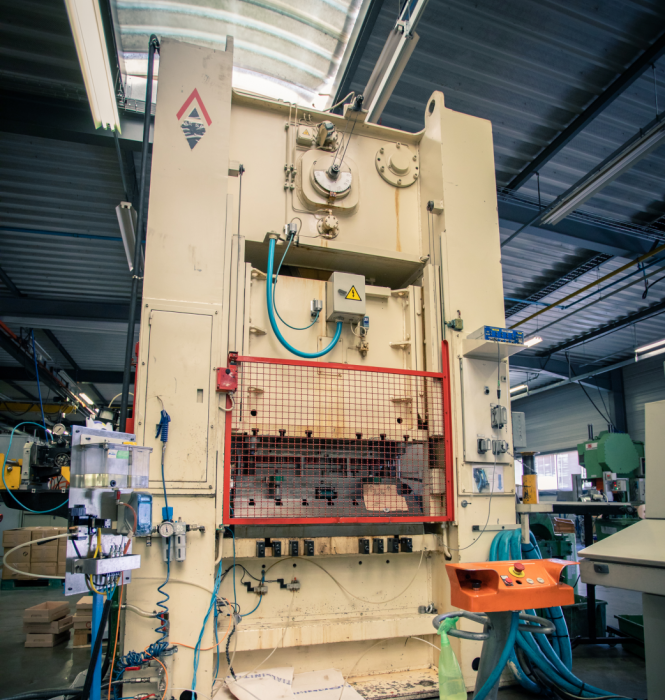

Traditional presses

Our traditional cutting workshop has 14 presses from 20 to 250 tons offering reactivity, flexibility and precision.

- High precision for the design of complex parts

- High production rate thanks to our BRUDERER type high-speed presses

- Realization of assemblies integrated in the tool (tapping, crimping, contacting...)

Multi-slide method

Cutting

with slides

multiple

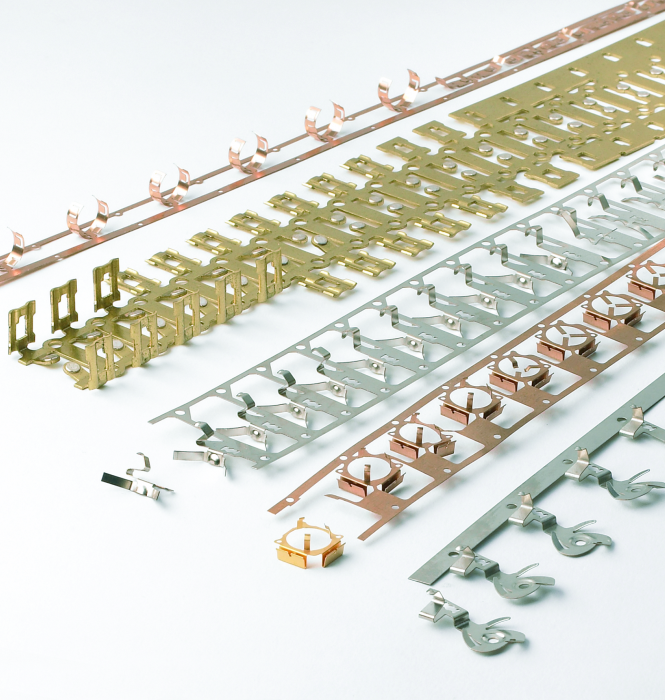

DCM Précision's press lines can produce a wide range of metal parts, from a large choice of materials and thicknesses.

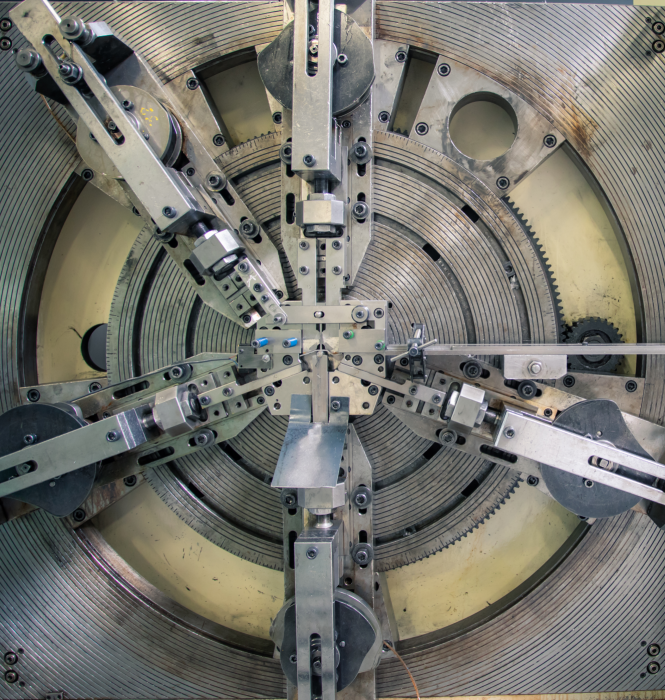

The multi-slide presses

Equipped with 7 presses from 25 to 125 tons, our machine park meets all your functional needs.

- Reduction of tooling costs for the design of complex parts

- Limitation of the risks of embrittlement of the parts thanks to the bending carried out in the direction of rolling of the strip

- Part width equal to the strip width, which allows for minimum material waste

- Numerous bends possible on the parts with the addition of additional processes such as welding, tapping or riveting

Cut raw materials

What thicknesses?

Our different presses allow us to work on a wide range of thicknesses from 0.05 to 3 millimeters.

What materials ?

- Steel

- Aluminium

- Bronze

- Copper

- Stainless steel

- Brass

- All alloys and precious metals

A global solution

From design to completion...

...always more precision !

Welding

Tapping

Crimp

Degreasing

Tribofinishing

Completion,

tribofinishing,

benefits

service

complementary

In order to increase the quality of our services and to respond with ever greater precision to your projects, we also ensure the assembly of sub-assemblies by welding, crimping, tapping, overmolding and plastic injection.

The integration marks our will to offer you parts with complete functionalities and a service going from the study to the completion.

Thanks to the recent investment in the latest technology equipment, we master the degreasing and deburring processes in-house.